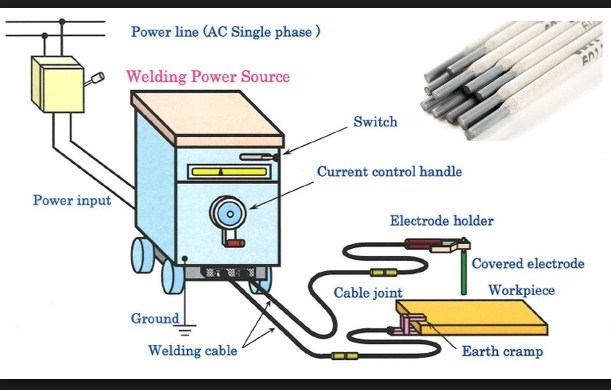

It is a type of welding that uses a welding power supply to create an electric arc between a metal stick electrode and the base material to melt the metals at the point of contact.

Arc welding machine parts and function.

Equipments required for electric arc welding.

2012 arc welding equipment part 1 welding power sources iec 60974 6.

Gas tungsten arc welding gtaw also known as tungsten inert gas tig welding is an arc welding process that uses a non consumable tungsten electrode to produce the weld the weld area and electrode is protected from oxidation or other atmospheric contamination by an inert shielding gas argon or helium and a filler metal is normally used though some welds known as autogenous welds or.

Running from the power supply is the transformer that provides you with the electric current that you need to form the electric arc.

A microprocessor then switches the stored energy into a transformed where it is converted into the desired output current.

The various equipments required for electric arc welding are.

Welding equipment includes stick welders tig welders mig welders multi process welders advanced process welders multi operator welders engine drives submerged arc equipment and wire feeders for arc welding.

2010 arc welding equipment part 6 limited duty arc welding power sources.

2002 personal eye protection.

Inverter welding machines produce the high voltages needed for high intensity arc welding.

A wide variety of welding machine parts and function options are available to you such as new.

As the electrode is brought near the base metal 2 4 mm apart where the welding is to be done spark or arc starts to produce in between the base metal and electrode.

Stick welding machine parts.

Arc welding is a welding process that is used to join metal to metal by using electricity to create enough heat to melt metal and the melted metals when cool result in a binding of the metals.

The machine stores the high voltage current from the wall outlet in a capacitor.

The basic stick welding set up involves a simple schematic.

The extension of the main transformer would be the two cables that work as the anode and cathode.

Machine shielded metal arc welding machine is the main parts of this process because without machine certainly we can not do welding process.

Transmittance requirements and recommended use.

Welding machine has a step down transformer to reduce the input voltage of 220 440v to 80 100v.

First on the electric power source ac or dc.

Fillers for welding and related techniques.